-

Handmade Damascus Steel Rat Tail Blank Blade for Knife Making Supplies "(BB117)Regular price $29.99

-

-

-

-

Handmade Damascus Steel Full Tang Blank Blade for Knife Making Supply "(BB104)Regular price $23.99

$29.99Sale price -

-

-

-

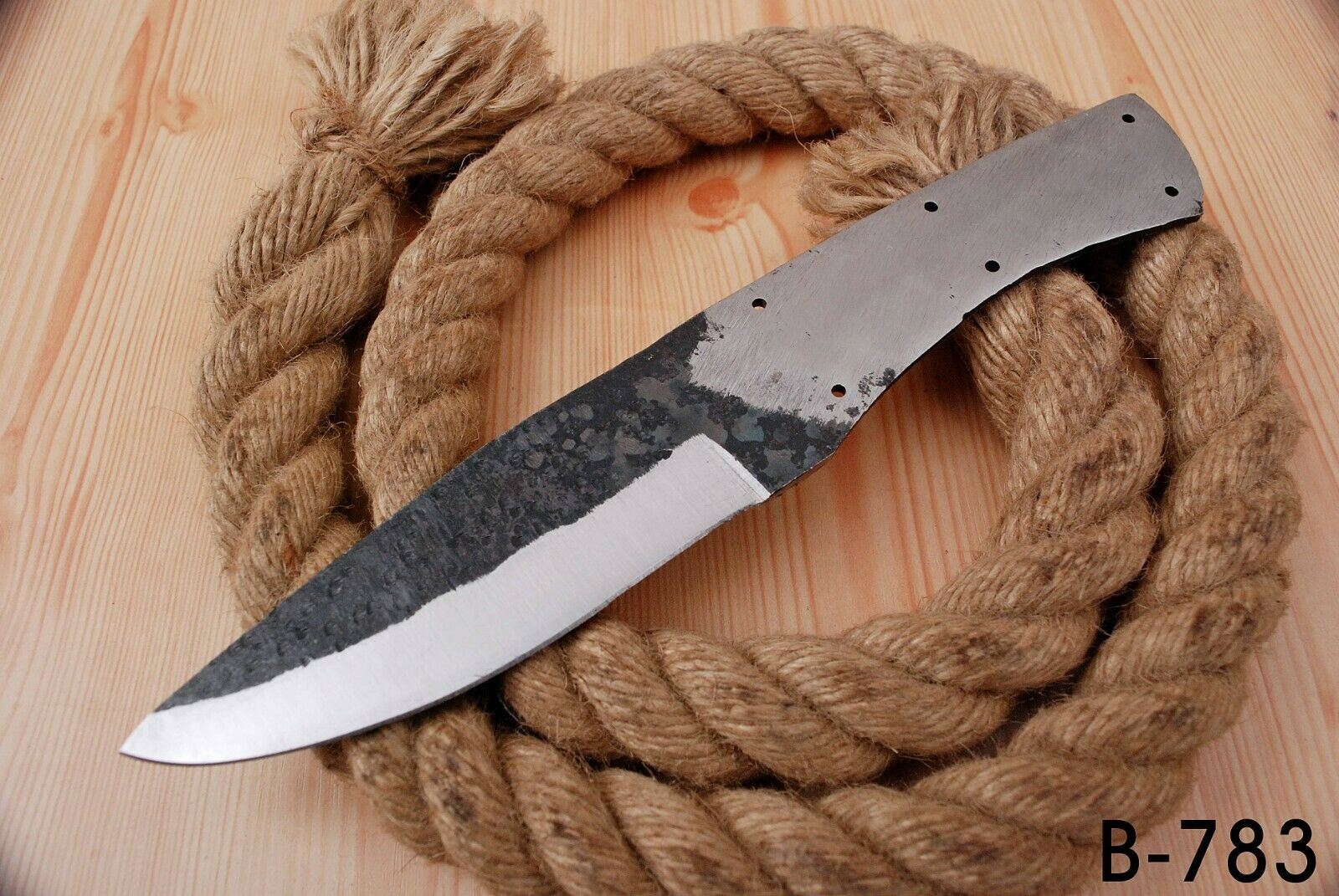

HAND FORGED DAMASCUS STEEL Blank Blade Hunting Knife Hammered Blade Knife MakingRegular price $18.39

-

Hand Forged Railroad Spike Carbon Steel Chef Knife Blank Blade for Knife MakingRegular price $23.99

-

-

The Best Knife Making Supplies By | SHARD BLADES |

Best Knife Making Supplies

Many handling and bundling enterprises utilize modern machine knives to cut items rapidly and successfully.

Quality artistry and materials are fundamental to a machine's sharp edge. Knifemakers and end-clients know accuracy makes sharp edges cut cleaner and extended length, and consistency in assembling guarantees their substitutions are similarly appropriate. That implies a superior quality finished result, longer runs, and less personal time.

Assume you're searching for a modern machine knife supplier. Also, you'll require an organization that conveys great sharp edges and stands behind its items with productive stocking, short lead times, tweaked arrangements, and solid deal support.

This is what to search for:

A Standing For Craftsmanship

Edge making, particularly for modern knives, is an accuracy creation. While new advancements might make it simpler or quicker, reliably delivering significant sharp edges testing. There's no viable replacement for Shardblades ' profundity of involvement, comprehension of the art, and capacity to collaborate with you to tackle issues.

Various Experience, Industry Center

Pick a producer that serves different applications inside the modern machine knife industry. Some knife creators represent many authors' specific ambiguous applications. Others give custom machine cutting edges yet audit various enterprises, for example, wood handling altogether handling.

You'll profit from working with an organization like Shardblades since we have experience in planning. And also assembling Chinese machines applications like bundling, changing handling, and printing.

Many Quality Materials

Cutting-edge material characterizes a knife's presentation. For example, more rigid steel cutting edges will endure longer; they might come up short on sturdiness to flex under tension or hold their edge. Adjusting material qualities to boost execution is the core of the knife producer's exchange.

Shardblades have immense involvement in the scope of preparation and different materials, including:

- High carbon prepares

- Tempered steels

- Tungsten carbides

- High-carbon, high-chromium apparatus prepares

- High velocity prepares

- Earthenware production

The Cutting-Edge Shapes You Want

The shape or math of a cutting edge decides its presentation. The right edge shape will cut items or bundles, neatly diminishing waste, destroying, or burring. Shardblades will match the edge or tooth state of existing knives or can work with you to decide the best edge calculation for your application, including:

- Straight

- Serrated

- Scalloped

- Sloped

Quality Coatings And Finishings

Coatings are as essential to your application as cutting-edge and tooth plans. Shardblades ratings like rating titanium nitride) and PTFE (Teflon) to help:

- Work on cutting

- Forestall erosion

- Diminish contact

- Limit adherence

Capacity to stock requests

Is the knife maker ready to stock your knives in the necessary volumes? An organization that can be a more significantly tremendous amount of its knives wants to serve its clients quicker. And also, at a lower cost for each edge than one that should fall on an edge without any preparation.

Shardblades hold the majority of our knives in stock. That implies up to 70% of orders are set out in the entryway immediately.

Volume evaluating

Does the knife maker offer volume More prominent Bigger quantities of knives can be delivered by more conventional crushing and complete than with explicit, custom knives? Hence organizations that emphasize cumin or minor clump handling might battle to coordinate the investment funds that an organization with volume valuing can offer.

Shardblades works intimately with clients to expect their requirements and change ours likewise. However, we can pass on reserve funds — now and then custom orders — because we stock again and again deal with our assembling interaction around the world. This gives us more control of expenses when sharp edges are specially made.

Why Shardblades?

Today Shardblades is the biggest provider of modern machine knives to handle and bundle together.

Our covalent quality, unparalleled help, and tremendous information on the modern machine knife space make us an esteemed accomplice and provider to organizations worldwide.